|

AUTOMATIC NOZZLE CHANGER

With the developing technology and Industry 4.0, speed is becoming more prominent in the industry.

Nozzle changeperformed manually reduces work efficiency and leads to losses in work times. For this

reason, there is a need for a system which will automatically perform the nozzle change process especially

in the machines that communicate with each other, automation systems and the machines whose work list

already defined to be cut. |

|

LINEER

Servo sürücüler ve lineer motor kombinasyonu ile kısa mesefalerde yüksek hızlara ulaşırsınız.

|

|

CUTLINE

Technology allows you to achieve better quality results on cutting surfaces compared to standard cuts.

|

|

AUTOMATION SYSTEMS

Enables you to automatically load and unload your machine.

|

| MACHINE MODEL | VENTO SERIES | ||||||

| VENTO 315 | VENTO 420 | VENTO 620 | |||||

| Sheet Dimensions | 1530mm x 3050mm / 5x10 ft | 2030mm x 4050mm / 6.6x13.2 ft | 2030mm x 6050mm / 6.6x19.8 ft | ||||

| Resonator (kW) | 4,6,8,10,12 | 4,6,8,10,12 | 4,6,8,10,12 | ||||

| Axis | X | 3050mm | 4050mm | 6050mm | |||

| Y | 1530mm | 2030mm | 2030mm | ||||

| Z |

80mm |

80mm |

80mm |

||||

| Working Table Height | 900mm | 900mm | 900mm | ||||

| Maximum Loading Capacity |

2000 kg | 3500 kg | 6000 kg | ||||

| Positioning System |

Linear Motor | Linear Motor | Linear Motor | ||||

| Acceleration | 30 m/s² | 22 m/s2 | 22 m/s2 | ||||

| Axis Speed (X,Y Simultaneous Speed) |

240 m/min | 200 m/min | 200 m/min | ||||

| Positioning Accuracy (Pa)* |

0.05 mm | 0.05 mm | 0.05 mm | ||||

| Shuttle Table Change Time | 27 sec | 35 sec | 45 sec | ||||

| Controller | 19" Multi Touch Screen | 19" Multi Touch Screen | 19" Multi Touch Screen | ||||

| Assist Gas | Oxygen (O2) : 15 Bar Nitrogen (N2) : 25 Bar |

Oxygen (O2) : 15 Bar Nitrogen (N2) : 25 Bar |

Oxygen (O2) : 15 Bar Nitrogen (N2) : 25 Bar |

||||

| Optional Equipments |

-Auto Nozzle Changing

-Loading/Unloading System

-Air Cutting

-Cut Line Technology

-Piercing Sensor & Cut Detection** |

-Auto Nozzle Changing

-Loading/Unloading System

-Air Cutting

-Cut Line Technology

-Piercing Sensor & Cut Detection** |

-Auto Nozzle Changing

-Air Cutting

-Cut Line Technology

-Piercing Sensor & Cut Detection** |

||||

| Machine Weight | 16000 kg | 20500 kg | 27000 kg | ||||

| CUTTING PARAMETERS | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Resonator | 4 kW | 4 kW CutLine |

6 kW |

6 kW CutLine |

8 kW |

8 kW CutLine |

10kW |

10kW CutLine |

12kW |

12kW CutLine |

|

Maximum Cutting Capacity |

Mild Steel |

20mm | 20mm | 20mm | 25mm | 20mm | 30mm | 25mm | 30mm | 25mm | 30mm |

| Stainless | 12mm | 15 mm | 20mm | 25mm | 30mm | 30mm | 30mm | 30mm | 30mm | 30mm | |

| Aluminum | 10mm | 15 mm | 20mm | 25mm | 30mm | 30mm | 30mm | 30mm | 30mm | 30mm | |

| Brass | 6mm | 8 mm | 12mm | 15mm | 15mm | 15mm | 20mm | 20mm | 20mm | 20mm | |

| Copper | 6mm | 8mm | 12mm | 15mm | 15mm | 15mm | 15mm | 15mm | 15mm | 15mm | |

| Power Consumption 380V/3PH ±%5 | 32 kVA | 48 kVA | 65 kVA | 85 kVA | 105 kVA | ||||||

|

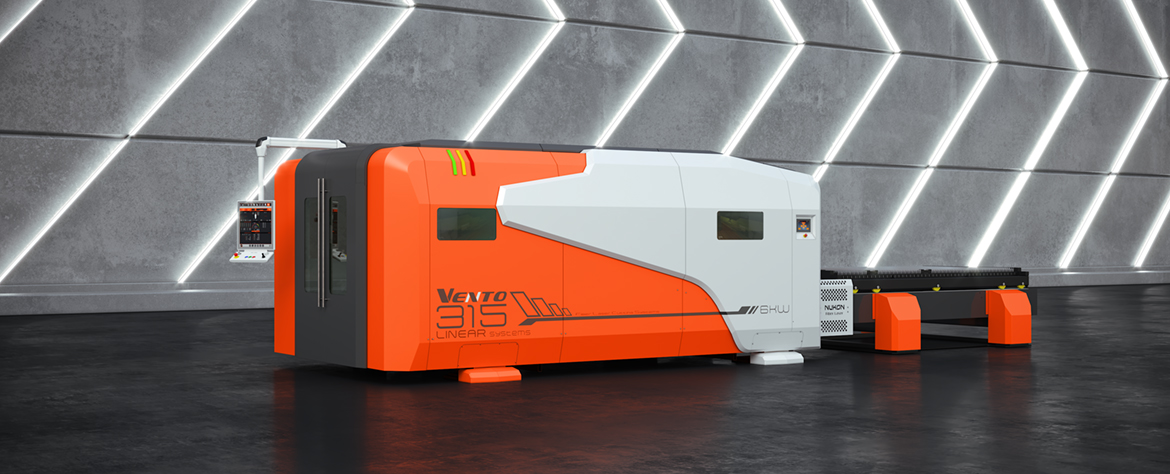

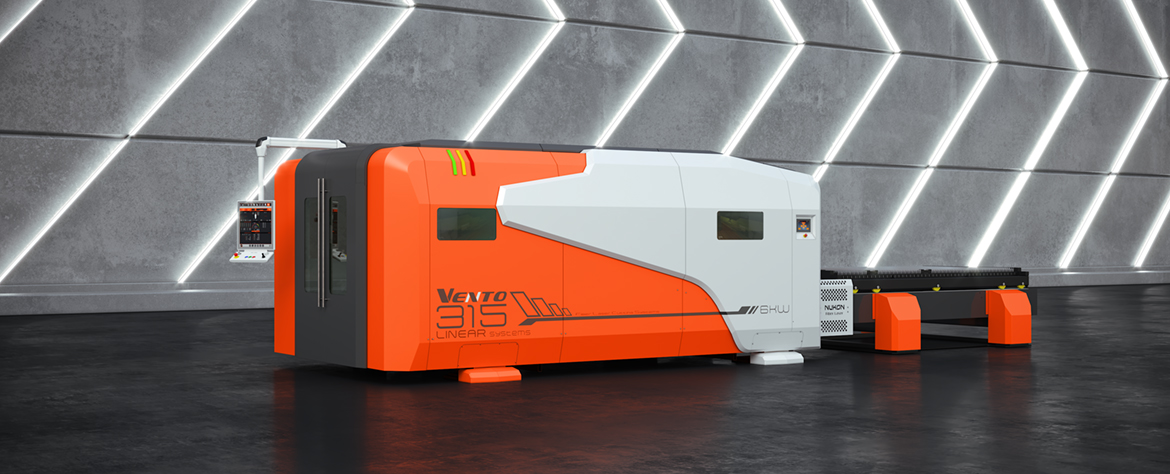

RACE WITH SPEED FOR SUCCESS..

Yeni tasarımımız, Vento serisi yüksek üretkenliğe ve standartlara sahip üst segment lazer tezgâhıdır. Ödüllü yeni dizaynı ile sadece göz zevkinize hitap etmez, aynı zamanda rekabette bir adım

öne çıkmanızı sağlayacak teknolojik üstünlüklere de sahiptir.

|