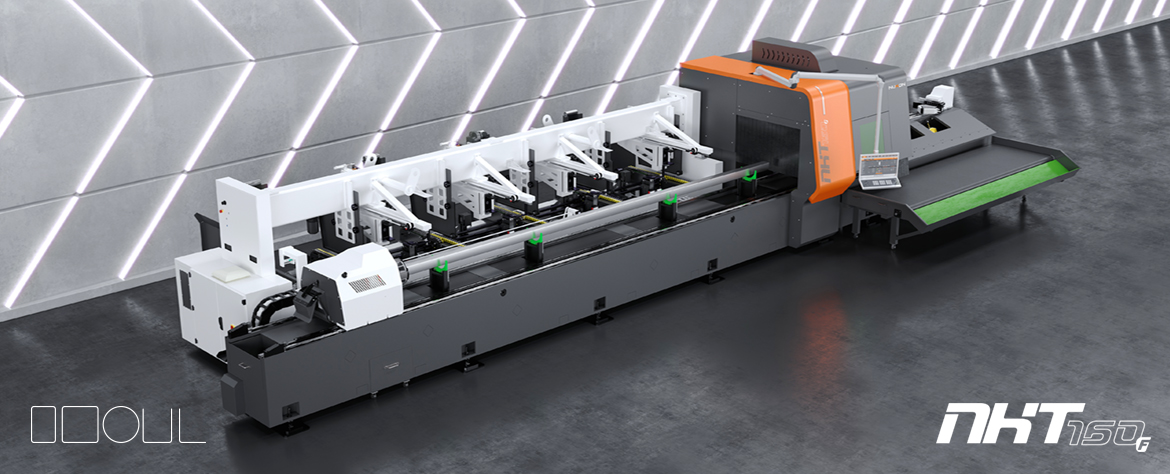

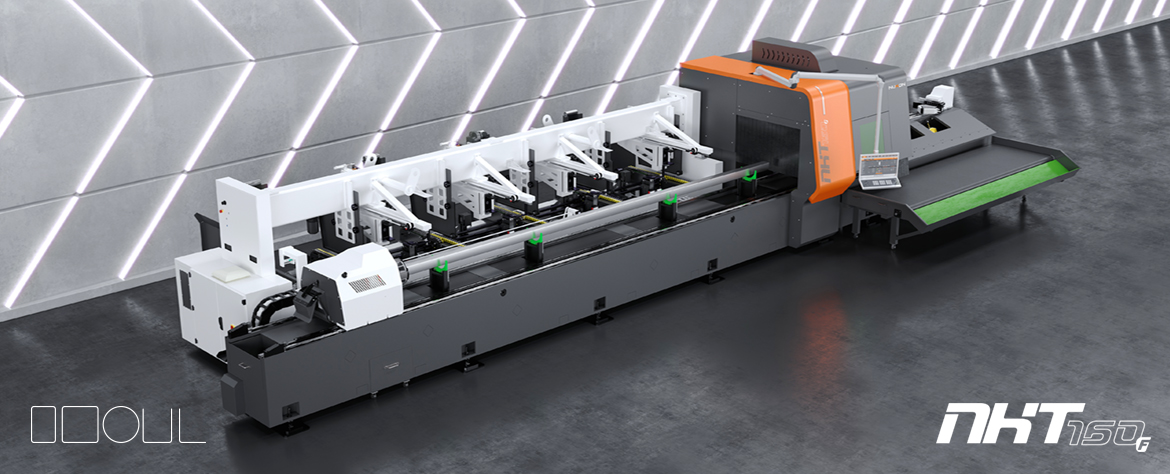

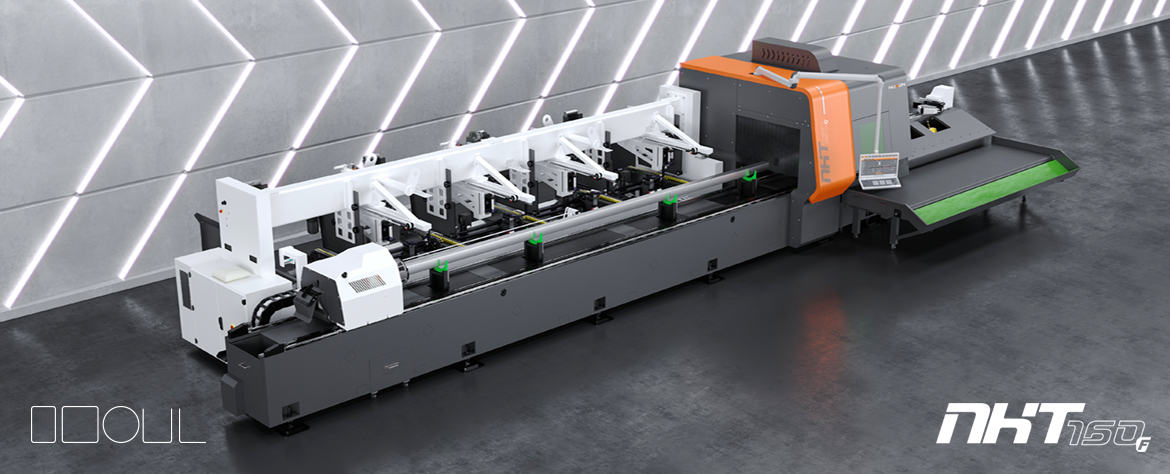

PIPE and PROFILE CUTTING MACHINE

|

|

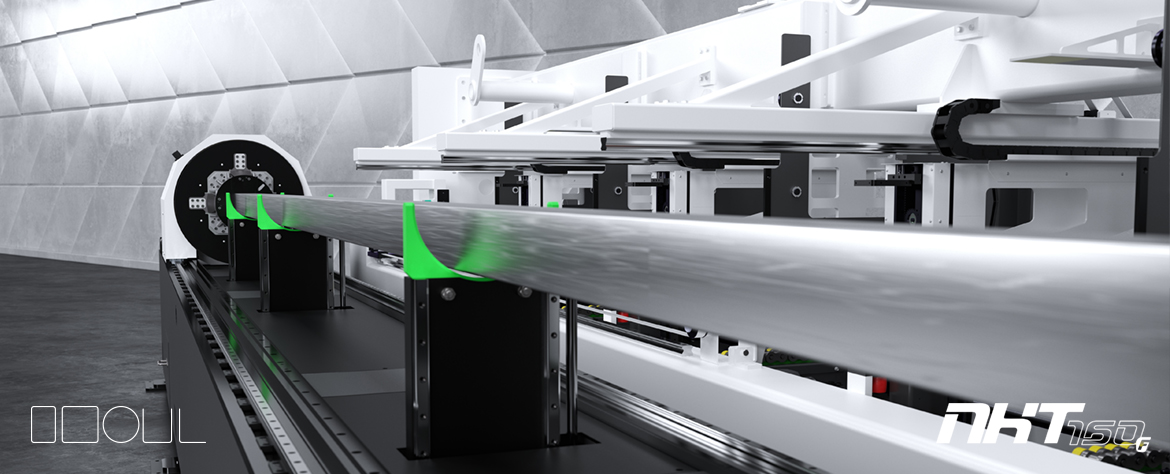

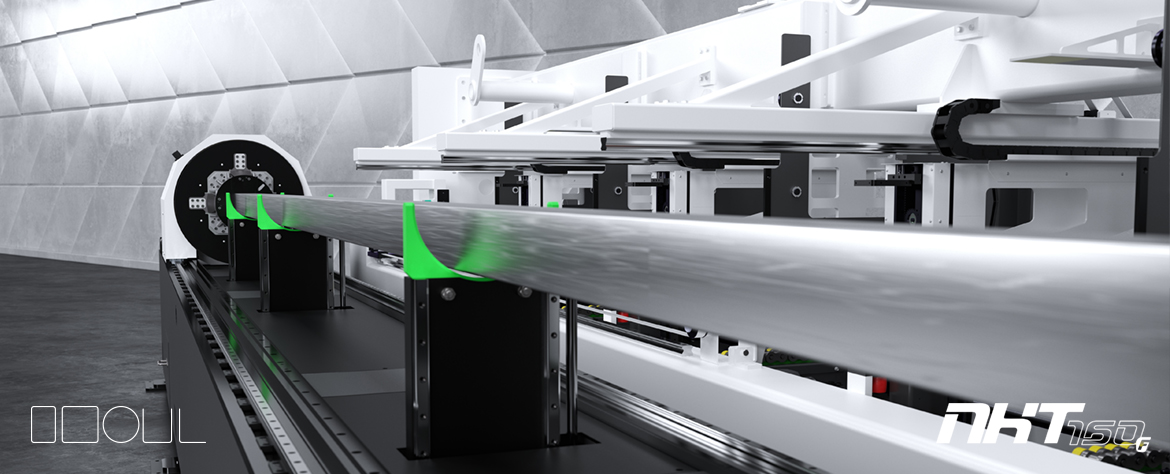

FEEDING CHUCK

The feeding chuck can hold materials between Ø15-Ø226mm in the center axis precisely. Jaw clamping works with a pneumatic drive with adjustable pressure. The profile rotation axis and profile driving axis are servo-motor driven. |

|

FRONT CHUCK The front chuck can hold materials between Ø15 andØ226mm precisely in the center axis with 4 supported roller jaws. Jaw clamping works with a pneumatic drive system with adjustable pressure.The front chuck has the ability to move forward and backward to cut the minimum residual material and long contours without using the micro-joint option. |

| Machine Model | NK-T160 | |||||

| Type | Pipe and Profile Cutting Machine | |||||

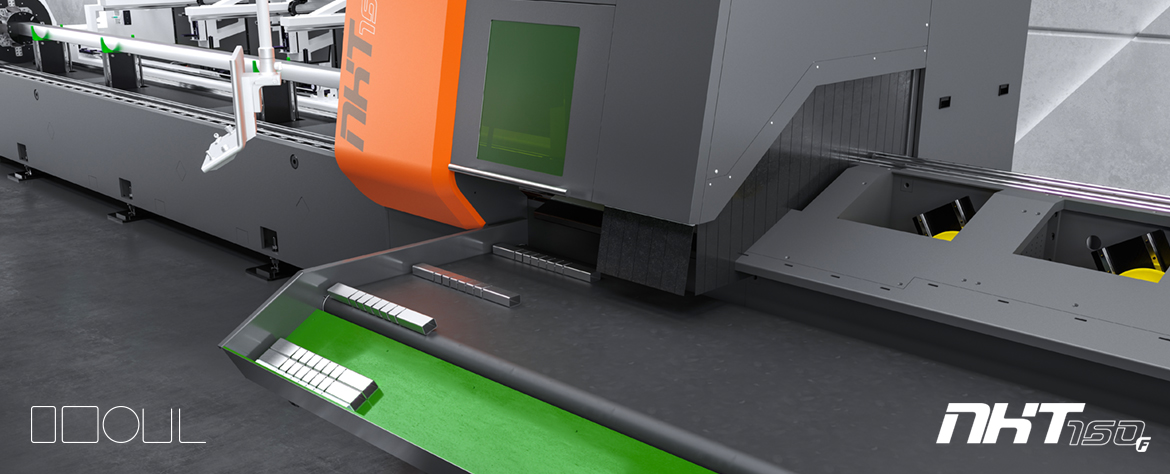

| Resonator | 1 kW | 2 kW | 3 kW | |||

Maximum Cutting Capacity |

Mild Steel | 5mm/.19" | 8mm/.32" | 10mm/.39" | ||

| Stainless Steel | 3mm/.11" | 6mm/.23" | 8mm/.32" | |||

| Aluminum | 2mm/.07" | 5mm/.19" | 8mm/.32" | |||

| Brass | 1,5mm/.06" | 3mm/.11" | 5mm/.19" | |||

| Cooper | 1,5mm/.06" | 3mm/.11" | 5mm/.19" | |||

| Max. Outer Circle Diameter | Ø 226mm/8.90" | |||||

| Max. Pipe Diameter | Ø 226mm/8.90" | |||||

| Max. Square Dimension | 160mm/6.30" | |||||

| Max. Rectangular Dimension | 200mm X 100mm | |||||

| Profile Cutting |

U, L

I*, H* (with Bevel option) |

|||||

| Feed Length |

6500mm/21.32ft,

8000mm*/26.24ft* |

|||||

| Max. Loading Weight | 35 kg/m | |||||

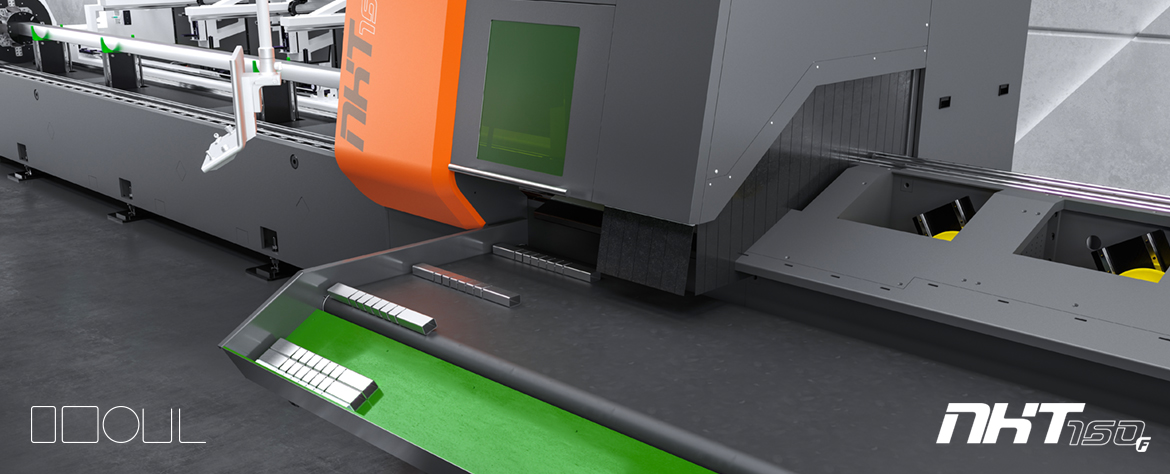

| Remnant | 80mm/3.15" | |||||

| Options |

- Automatic Centering - Weld Seam Detection- Bevel Cutting |

|||||

| Control Panel | 21" Multi-Touch Screen | |||||

| Machine Weight | 23000 kg / 50706 lbs | |||||